Pattern Matching

Perfectly match your pattern repeats and get the most from your fabric with Pathfinders’ suite of pattern-matching solutions.

“PathWorks is the best and only dedicated system for the Furniture Industry that operates within a single program !”

John Hollo

Director, Pathfinder

Manufacturing Pattern Matched products require a digital file (CAD) and a sophisticated cutting system (CUTTER).

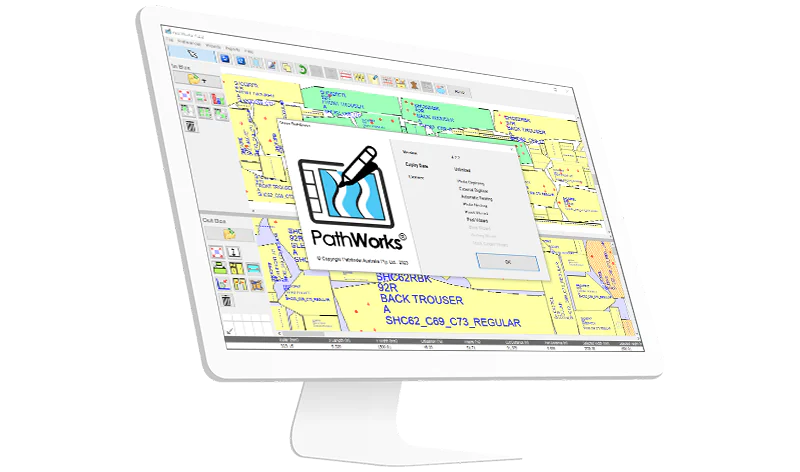

CAD – PathWorks is Pathfinder’s solution for generating Pattern Matched nested files, also known as ‘markers’ within patterned fabrics. PathWorks has unique features making it more powerful and easy to use than any other system. The association between shapes can be linked which means new nested files can be created automatically within seconds to adapt to new fabric patterns. Flow Matching is a breeze with features enabling multiple stripe and motif repeats within the same fabric and translating this to the automated cutting process automatically in a meaningful way.

CUTTER – Pathfinder cutters offer two solutions for Pattern Matching. Pathfinder’s solutions provide a multitude of benefits for manufacturers of Furniture, Apparel, Automotive, and many other industries that require specific piece alignment. Pathfinder’s solutions are highly versatile because they can seamlessly work with industry-standard CAD files, making them suitable for a range of applications. A user-friendly interface makes it easy to learn, saving time, labour and fabric.

PM (Pattern Matching) – Enables the operator’s total control of piece placement. Positioning and skew of every piece can be validated by a laser or camera mounted within the cutting system.

APM (Adaptive Pattern Matching) – Sophisticated solution that will automatically adjust nested shapes to conform to variable fabric repeats, bows and skews. The onboard camera will automatically identify fabric patterns and make neccessary adjustments on the fly.

Pattern Matching

Any of the range of Pathfinder Single-Ply or Multi-Ply cutters can be fitted with either Pattern Matching (PM) and/or Adaptive Pattern Matching (APM) software.

The Pathfinder Pattern Matching (PM) solution aligns patterns across cut parts with pinpoint accuracy from any striped, plaid or motif material.

When producing a pattern matched product, it is important the pattern flows seamlessly across multiple panels within the product. Pathfinder’s tools enable perfect matching across a variety of product groups and retains essential rules around how the product was matched, maintaining consistency over time.

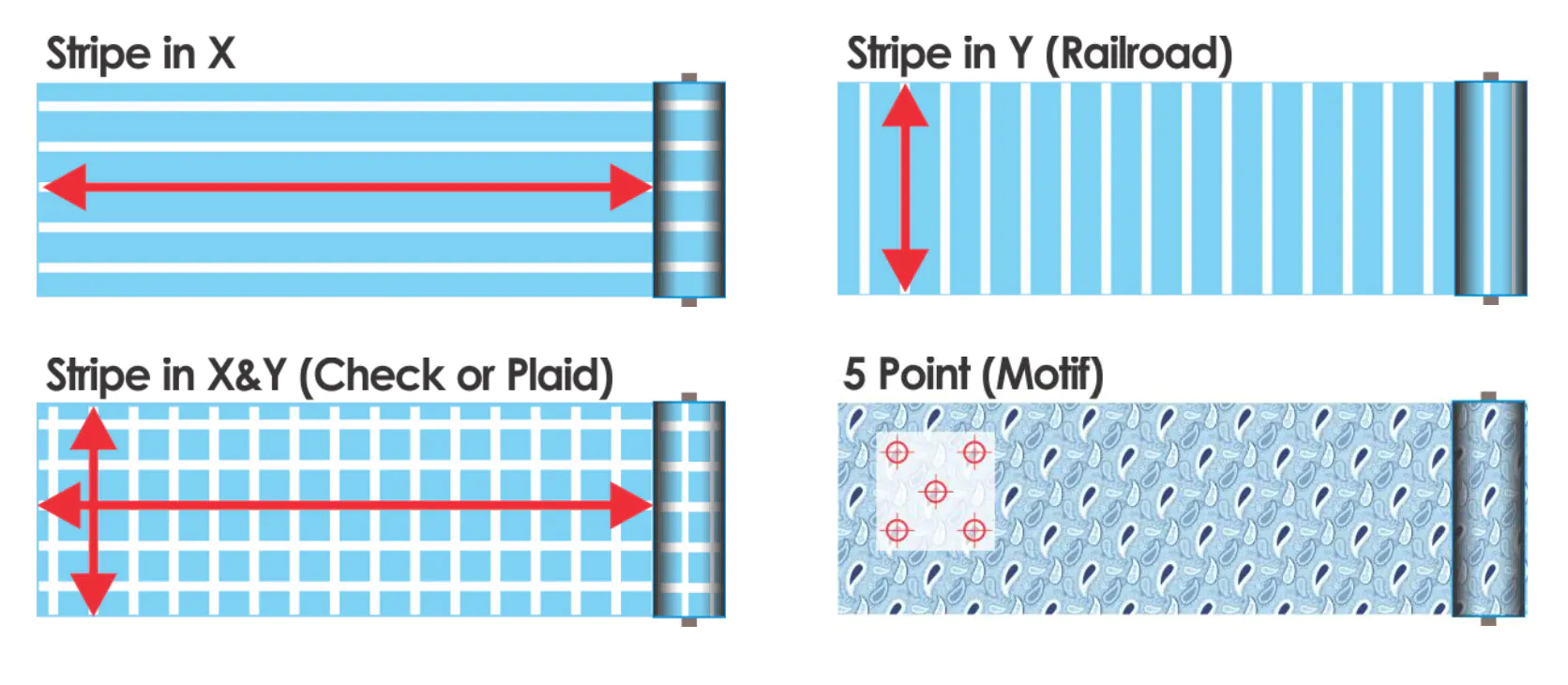

What defines a pattern?

There are 4 main types of patterns that can be matched in the Pathfinder Pattern Matching system.

The Pathfinder PM system makes it as easy to cut patterned fabric as it is to cut plain fabric. Once the pattern match points have been scanned, the PathCut system adjusts the marker pieces to perfectly align with the pattern and best utilisation of the fabric. The time, labour and material saved will dramatically speed up the workflow for any operation in Furniture, Fashion & Apparel.

Adaptive Pattern Matching

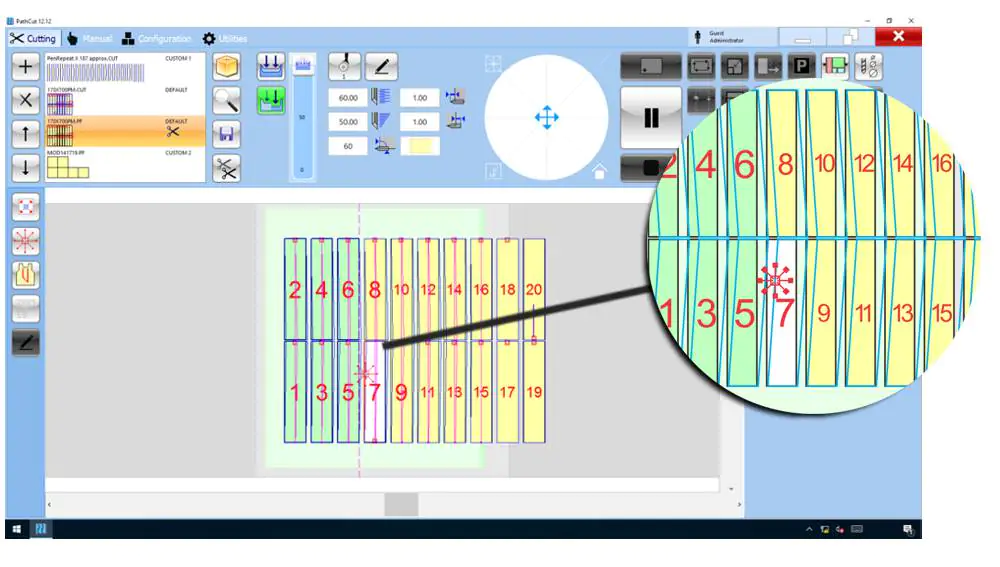

Often the orientation and spacing of the pattern tends to vary significantly between and within rolls of fabric. This is a natural consequence of variations in manufacturing and handling prior to cutting. Adaptive Pattern matching compensates for these variations by adapting the marker to the fabric at the time of cutting.

Using PM or APM is a simple and straightforward process thanks to an easy to use interface and semi-automatic precision checking. The entire workflow from roll feeding through to cutting requires just one operator with minimal training – which reduces labour costs and eliminates production bottlenecks.

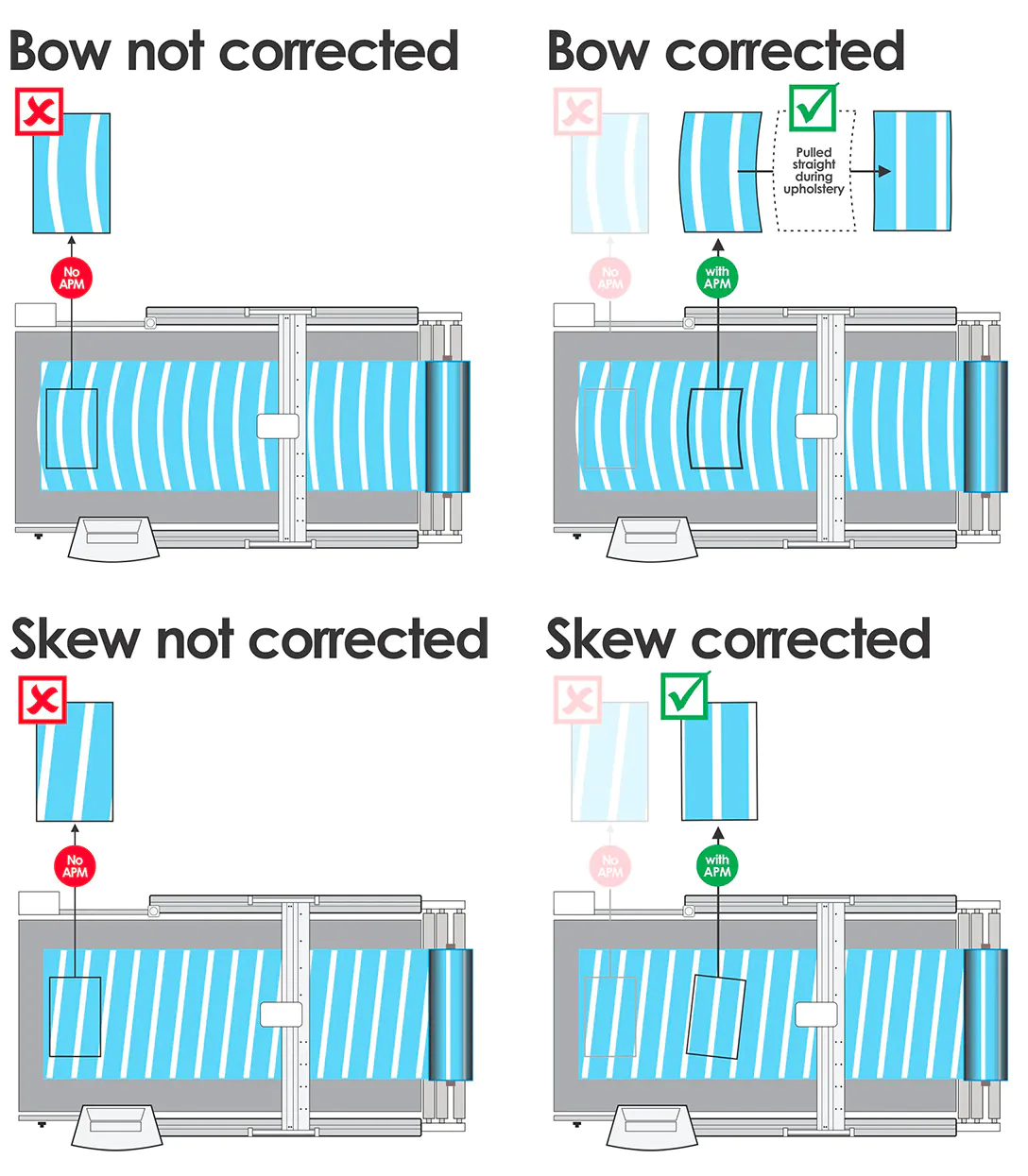

Bow and Skew correction

The Pathfinder Bow and Skew correction solves the issue of material distortion off the roll. Pattern repeat point distortion is captured via the Head Camera and with minimal operator effort, the distortion points are mapped and the software then automatically matches the bow or skew to the individual pieces (shown above). The original cut piece is outlined in black. The corrected Bow or Skew cut path is shown in blue.

Even the worst Bow and Skewed fabric will be automatically corrected on the fly!

Pattern Matching and Adaptive Pattern Matching solutions are available for all of the Pathfinder range of Single-Ply and Multi-Ply cutters. Save up to 75% in labour, time and material and get more power in your cutting room for a fraction of the cost of other solutions!

Cutting Room Solutions for the Furniture Industry

The Pathfinder range of solutions for Furniture Industries is designed to be the most advanced systems available and are known for ease of use, high cut quality and productivity.