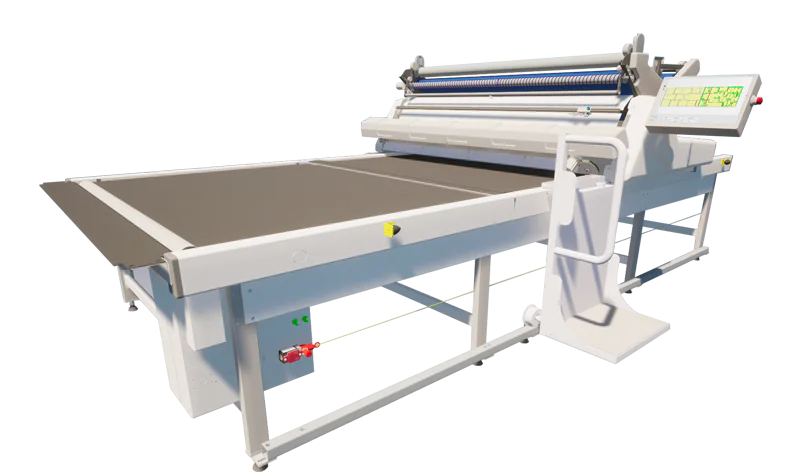

Roll Feeding

EasyFeeder™: automatically feeds rolled goods ‘tension-free’ into the cutting system while maintaining precise edge alignment.

Material Handling solutions that work

The Pathfinder EasyFeeder is designed to deliver a single layer of material synchronised with the Pathfinder cutting system. Rolled goods are conveniently loaded at table height, reducing the risk of operator injuries. Unlike other roll delivery systems, this system does not require an operator to bend down or lift rolls above a cradle which will increase the risk of personal injury. Furthermore, there is no bar required to be inserted through the core.

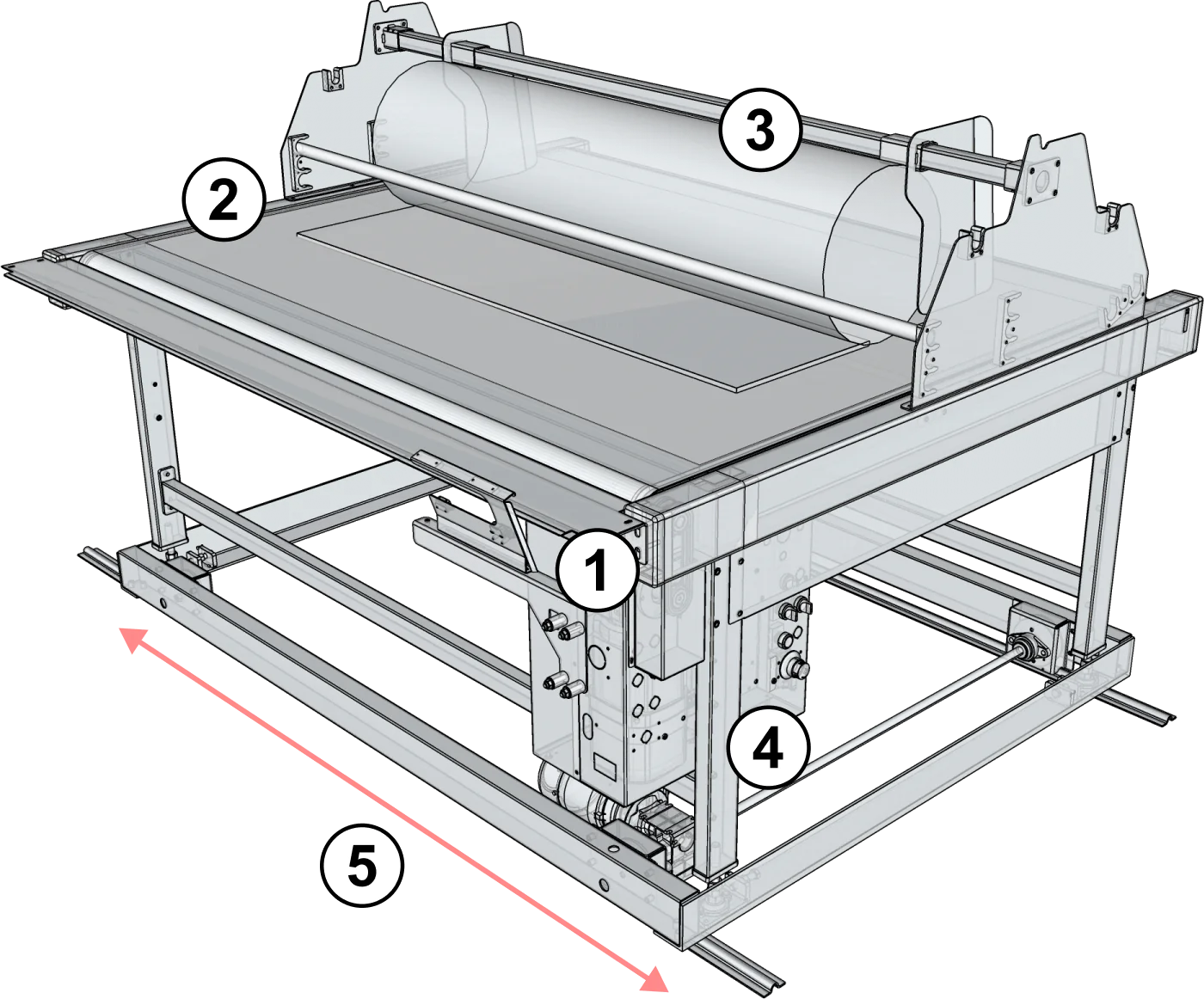

- Electronic edge control

- Conveyor Belt

- Fabric roll

- Control Box

- Lateral movement

Features

- Increased cut part quality by eliminating material distortion

- Increased productivity

- Manual/Automatic feed mode selection

- Manual/Automatic edge control

- Forward/Reverse

- Modular construction

- Tension-Free Roll Feeding

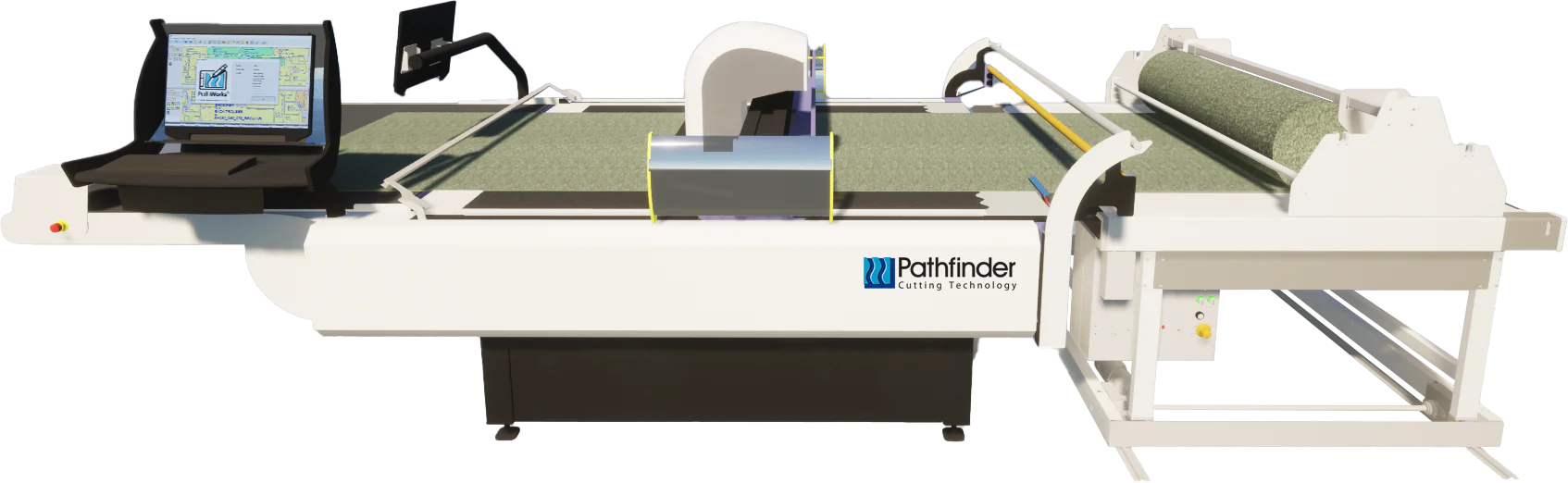

- Full synchronization with Pathfinder cutter

- Electronic Fabric Edge Alignment

Available in various widths

With four versatile models to choose from, ranging from 2020mm to 4120mm in width and an adjustable height of 845mm to 905mm, EasyFeeder is designed to optimise your operational efficiencies.

Maximise your profits

Electronic Fabric Edge Alignment

When cutting directly from a roll, it is important that the fabric edge is delivered correctly into the cutting machine.

This ensures all pieces are cut within the material width and eliminates the need for realignments.

The EasyFeeder is fitted with sensors that detect the fabric edge and automatically makes lateral adjustments to ensure the fabric edge is delivered correctly into the cutting area.

Material Rewind

When a roll is no longer needed, it can be easily re-wound at a press of a button and removed, ready for the next job.

Full synchronization

The EasyFeeder delivers material synchronised with the Pathfinder cutting system. This eliminates material distortion often a result of “stretching” when pullling from a roll.

Tension-Free Roll Feeding

The Pathfinder EasyFeeder is a roll feeding device synchronised with the Pathfinder cutter, designed to increase productivity and profitabiIity.

Request more info

Want to know more? Contact us!

Combine with other products

Pathfinder presents a comprehensive end-to-end solution tailored to meet the needs of diverse businesses by offering a pre-established material cutting room. Irrespective of production scale, our cutting machines are designed to cater to even the most exacting requirements of enterprises.