CUSTOMER STORY

Both the company and its cutter convinced us right away and we decided to replace one of our machines with a Pathfinder. Since then, the cutter has been working without any problems at an average of 8-10 hours a day.

ZCK improves cut quality with a Pathfinder

Looking for an alternative to our existing cutters, we came across Pathfinder over 2 years ago. Both the company and its cutter convinced us right away and we decided to replace one of our machines with a Pathfinder. Since then, the cutter has been working without any problems at an average of 8-10 hours a day. With a virtual “plug and play“ installation and because of the structured user interface, we had the machine running and the operators trained within almost no time (about 2 days) and without any major production downtimes.

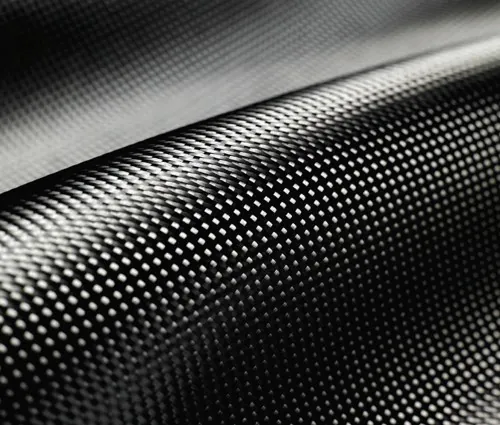

Thanks to Pathfinder, we have improved the quality of our cuts of a variety of materials (fabrics, glass fibers, insulating material, prepreg fibers, cardboard, imitation leather…) and increased the productivity with both single and multiple layers.

As the Pathfinder is very economical regarding maintenance costs and the consumption of wearing parts (knives, sharpening stones, bristles), we have been able to reduce the running costs by more than 60% compared to the previous costs.

Due to this highly positive experience with Pathfinder and the subsequent benefits for our company, we are considering the possibility of replacing our second cutter with another Pathfinder.

It is our pleasure to recommend the products of Pathfinder to anyone who is interested.