Production Analyst

Empowering Smart Manufacturing

Designed to optimize production processes, Production Analyst enables businesses to make data-driven decisions, enhance efficiency, and streamline resource allocation.

What is Production Analyst?

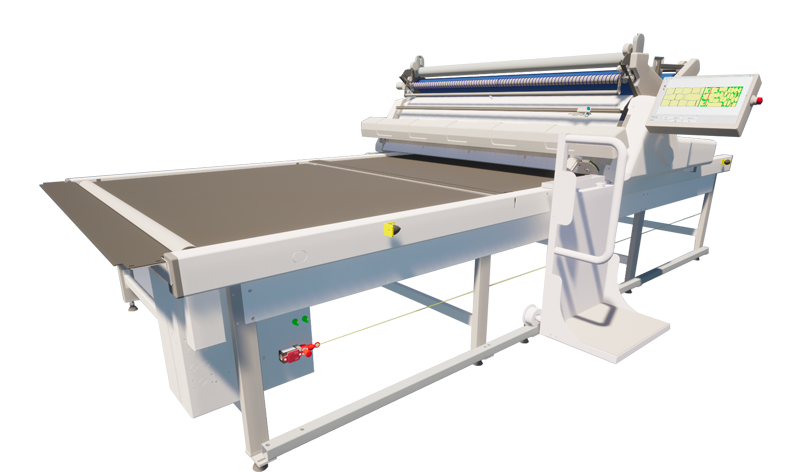

Production Analyst is a standalone software program that works in conjunction with Pathfinder’s conveyorised cutting machines. Pathfinder’s machines record key metrics including cutting activity, maintenance activity and maintenance schedules in the database.

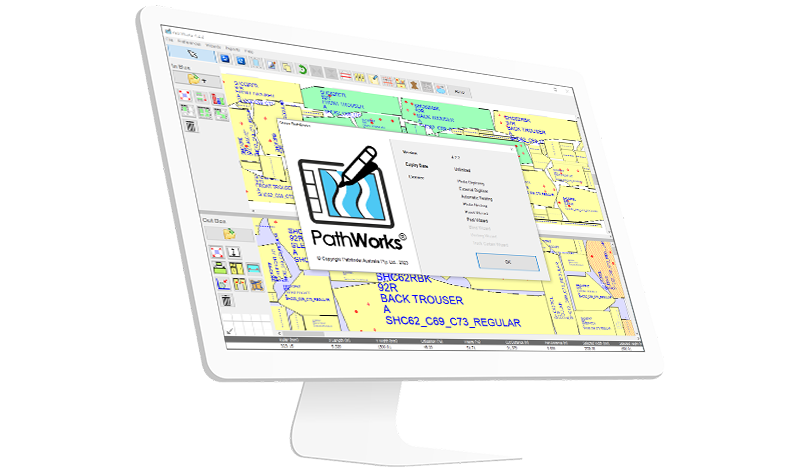

Production Analyst is a valuable tool connecting data from Pathfinder cutting machines. Data can be processed to generate detailed production reports for specific timeframes, sites, machines, and operators. Additionally, the program provides reports on actual and predicted consumption of consumables, including knives, stones, and paper/plastic for specified periods. This predictive feature helps with inventory management and reduces material waste, ultimately leading to cost savings and enhanced efficiency.

Features

- Data Integration

- Comprehensive Reporting

- Predictive Analysis

- Optimized Production

- Reduced Material Waste

- Improved Resource Allocation

- Data-Driven Decision Making

- Enhanced Cutting Room Operations

Key Features

Data Integration

Production Analyst is a conduit to the cutting machines, efficiently collecting and organizing data. By integrating with Pathfinder’s cutting machines, it ensures relevant information is accurately recorded and readily available for analysis.

Predictive Analysis

Production Analyst goes beyond reporting by providing predictive analysis of consumables. By analyzing historical data, the system can forecast future consumption of knives, stones, and paper/plastic. This proactive approach ensures optimized inventory management and minimizes material waste, leading to cost savings.

Comprehensive Reporting

The heart of Production Analyst lies in its ability to generate comprehensive reports with unparalleled granularity. Production Managers can effortlessly access detailed insights into the cutting process, tracking marker data, knife changes, stone changes, and more. Analyze production metrics for specific periods, sites, machines, and operators, empowering you with actionable data to drive improvements.

Benefits

Optimized Production

Gain a holistic view of your production process, identify bottlenecks, and optimize cutting times, leading to enhanced productivity and efficiency.

Reduced Material Waste

Smart predictions and accurate resource planning reduce material waste, contributing to a more sustainable and eco-friendly manufacturing process.

Improved Resource Allocation

Streamline resource allocation by analyzing operator performance, ensuring tasks are assigned to the right team members for maximum productivity.

Data-Driven Decision Making

Make informed decisions based on real-time data and comprehensive reports, empowering your team to stay ahead in a dynamic manufacturing landscape.

Enhanced Cutting Room Operations

Centralize production data, improve coordination, and streamline workflows in your cutting room for smoother operations.