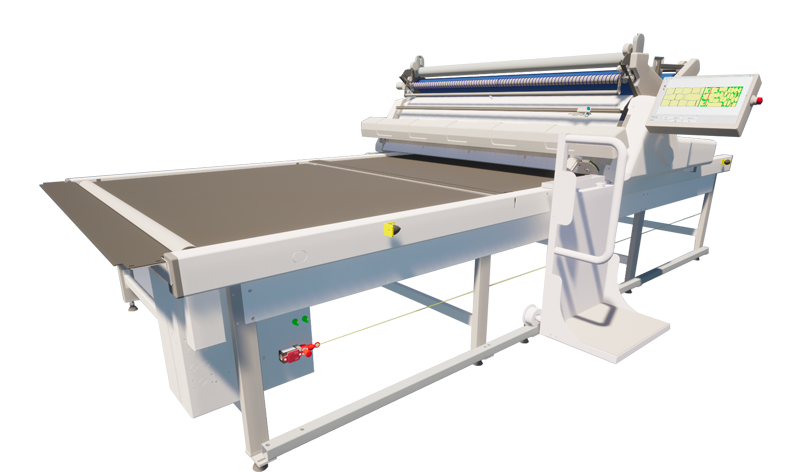

FabricPro™ – fully automated spreading machines

FabricPro™ is an advanced spreading solution for fabric rolls, offering tension-free spreading and perfect edge alignment. Available in various widths to suit your needs.

“First real innovation of fabric spreading in over 20 years”

John Hollo

Director, Pathfinder

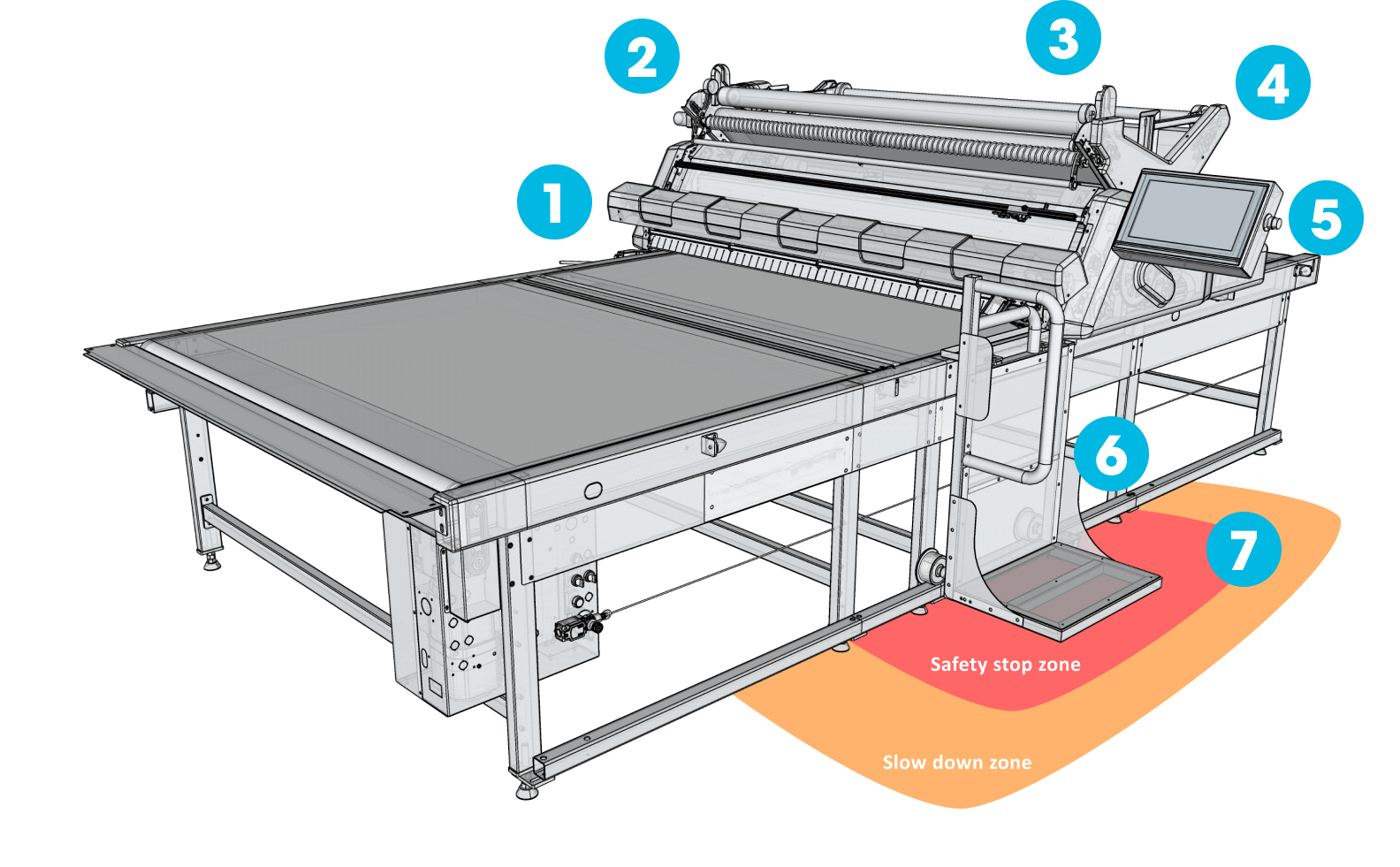

Tension Free Automatic Material Spreading

FabricPro™

- Cross-cutting

- Spiral Spreader

- Dancer Bar

- Fabric Cradle

- Touch Screen

- Travel Platform

- Safety Zone

Features

The patented cradle design simplifies the process of loading heavy rolls by lowering them to table height.

- Spreads woven and knit fabrics

- Intuitive colour Touch Screen Display

- Threading/Rewinding of fabric

- Spreading without fabric Clamps

- Face to Face or Face up spreading

- Tension-free spreading

- Electronic edge control

- Patented Cradle – lowers to table height

- LiDar safety sensors

- Pre-Set Parameters

- Automatic Spreading from the marker/nest file

- Automatic Splicing calculation with graphical marker visualisation

- Automatic Programmed Spreading from a ‘JOB FILE’.

Loaded with Standard Features

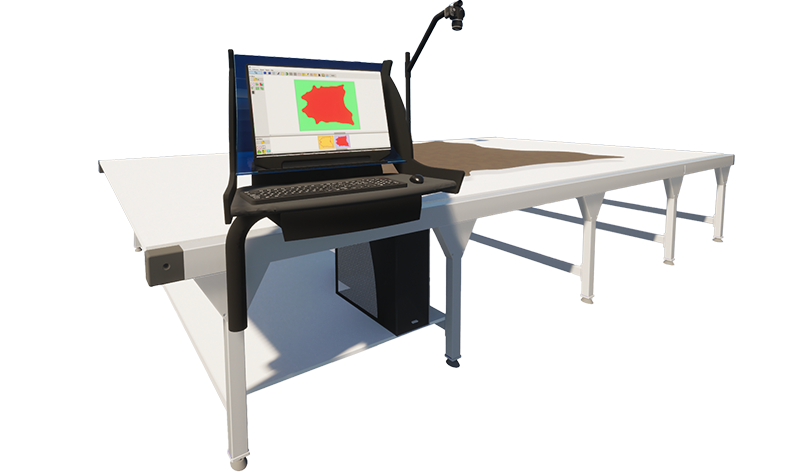

User Interface

- Large colour touchscreen

- Simplified graphical display that is easy to learn

- Stores unlimited fabric set-up files for quick retrieval to accelerate future spreading jobs

- Virtual throttle enables full control

- Dynamic digital speed control of all movements with a single slider

Safety

- LiDar multi-zone detection – slow down when objects or persons are detected in near proximity, and stop when in close proximity.

- Eliminate operator injury caused by lifting heavy rolls with a patented cradle enabling loading at table height.

- Automatic knife sharpening – the frequency of sharpening is adjusted automatically by fabric type within pre-set parameters. Operators do not need to place their fingers near the knife system to activate the sharpener.

Elevator

- Uniquely maintains a fixed angle – this guarantees the same fabric tension as the elevator raises

- Automatic calculation of changing fabric start edge synchronised with elevator height

- Automatic elevator height position calculated by ply height

Cradle (Patented)

- The cradle lowers to table height enabling heavy rolls to be loaded easily

- Feather-light dancer bar minimising tension – even difficult fabrics

- A fully enclosed endless belt eliminates jammed threads, often found in typical cradles

System Features

- Electronic edge control

- Integrated safety stop system

- Automatic knife sharpening

- Automatic spread programming from ‘job file’

- Automatic spread programming from ‘cut file’

- Splicing – Automatic Splice position calculation and restart

‘Out Of Fabric’ detection - Automatic elevator height positioning

- Ply counter

- Automatic Fabric Inspection Lightbox

- Programmable end allowance settings

- Spreading configurations – ‘Face-to-Face’, ‘Face-up’ & ‘Face-to-Face with end cut’

Total control

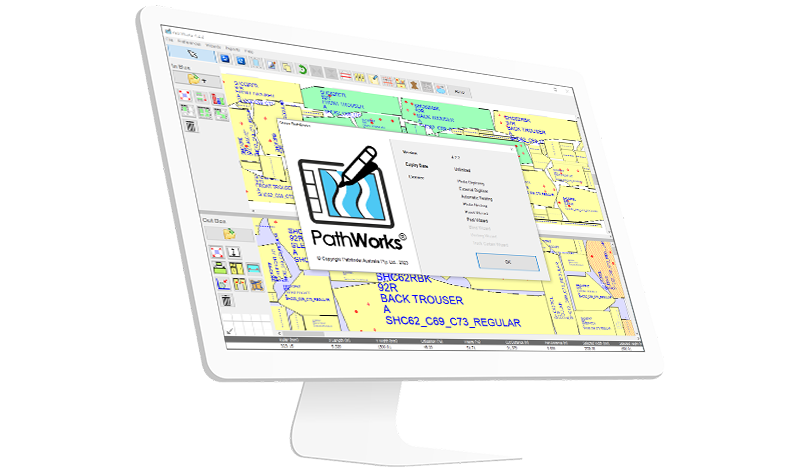

Job File – Automatic setup of spreading job

The Job File can be generated by the production team using Pathfinder’s utility program or within the FabricPro™operational software. FabricPro™recognizes the Job File and automatically associates the marker/nest with the spread job.

This facilitates splice functionality when fabric defects or the end of the roll is encountered, resulting in significant fabric savings.

- Identifies fabric name and characteristics

- Applies correct preset spreading parameters

- Sets correct numbers of spread plies required

- Automatically pauses machine prior to anticipated “out of fabric”

- Automatically sets spread length including und buffers

- Automatic splicing calculation and continue spreading

- Validation of remaining fabric or amount of fabric supplied

- Label generated identifying remaining lenght and fabric type*

*when optioned

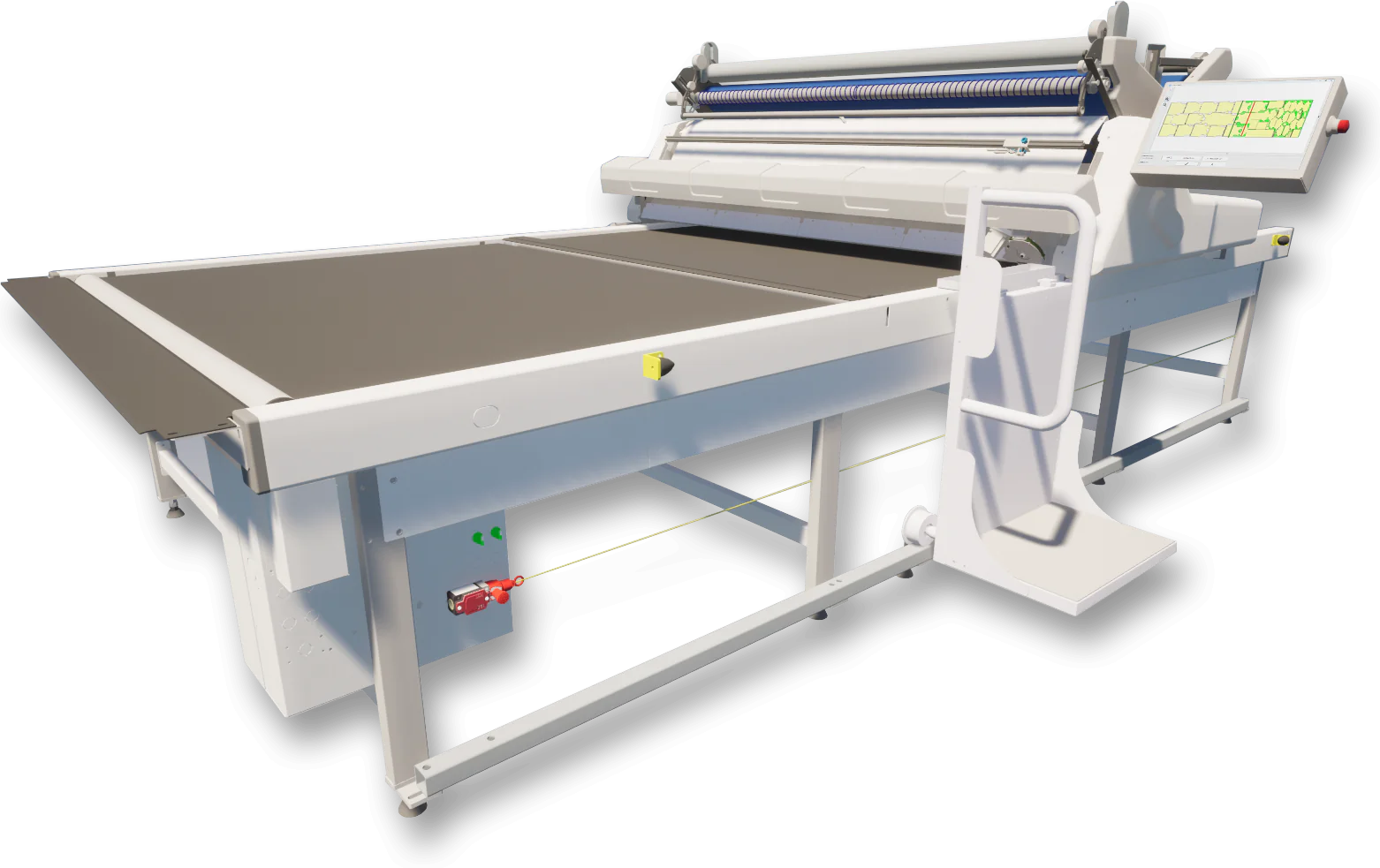

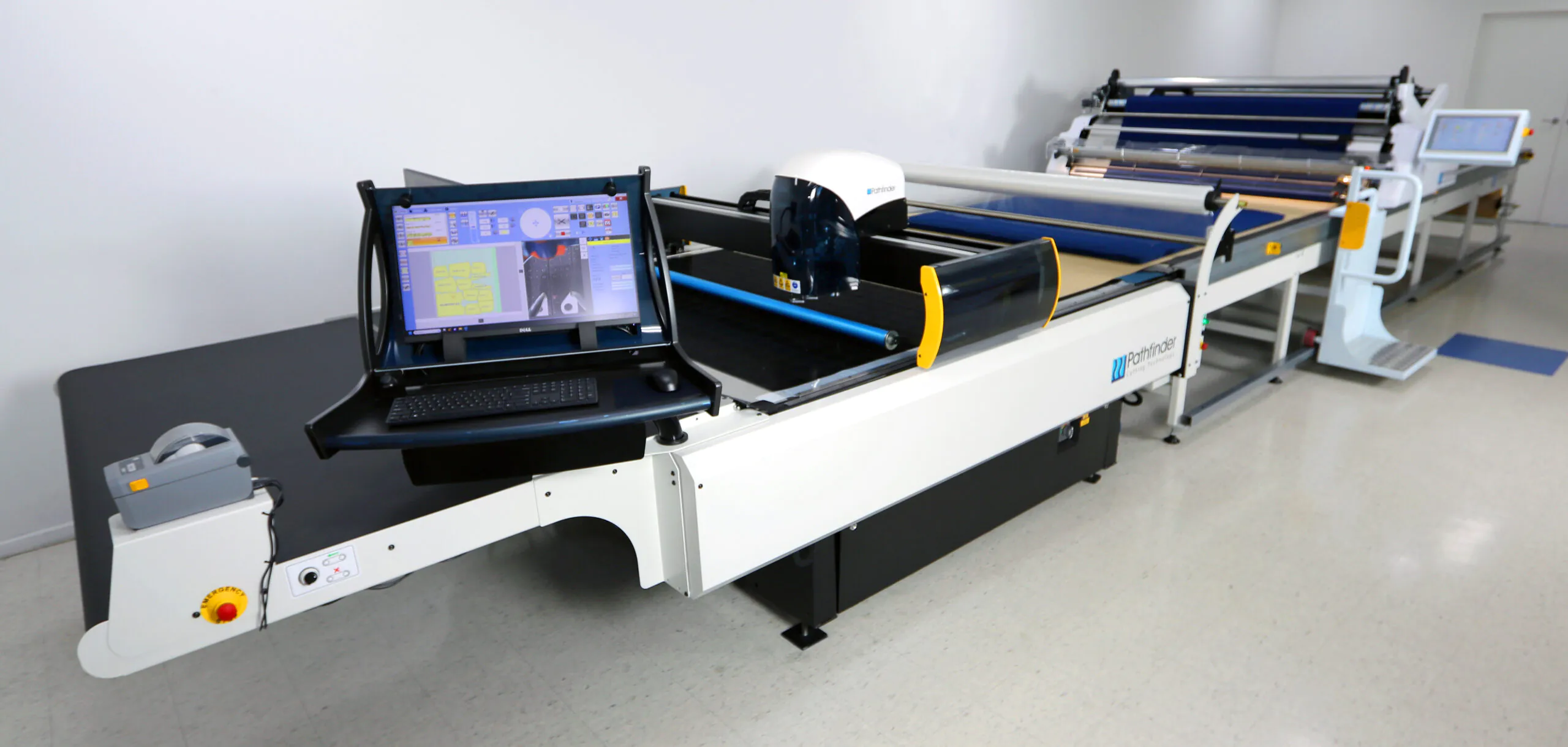

Automated spreading solution

The FabricPro™ is a reliable and robust automated spreading solution for fabric rolls weighing up to 100 kg (220 lbs). Spread without tension and with perfect edge alignment. Available in various widths to best suit your application.

Optimisation

Accurate spread length and edge alignment is the key to optimizing your fabric spreading operation. The FabricPro™ will easily spread your fabric to the desired spread lengths, minimizing fabric end loss and accurately aligning fabric edges.

Flexibility

For spreading fabrics from the roll, face-to-face spreading (zigzag) or face-up.

Combine with other products

Pathfinder presents a comprehensive end-to-end cutting and spreading solutions tailored to meet the needs of diverse businesses by offering a pre-established material cutting room. Irrespective of production scale, our cutting machines are designed to cater to even the most exacting requirements of enterprises.

Request more info

Want to know more? Full specifications are available on all of our automated spreading machines. To send you information that is relevant to your business please fill in the following details.