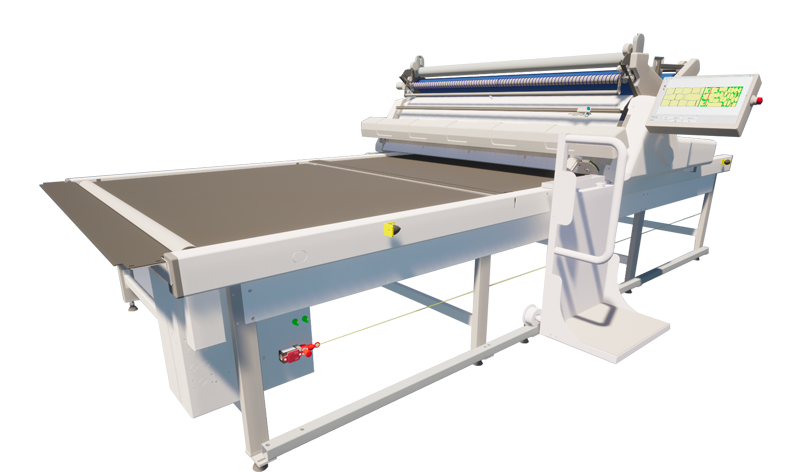

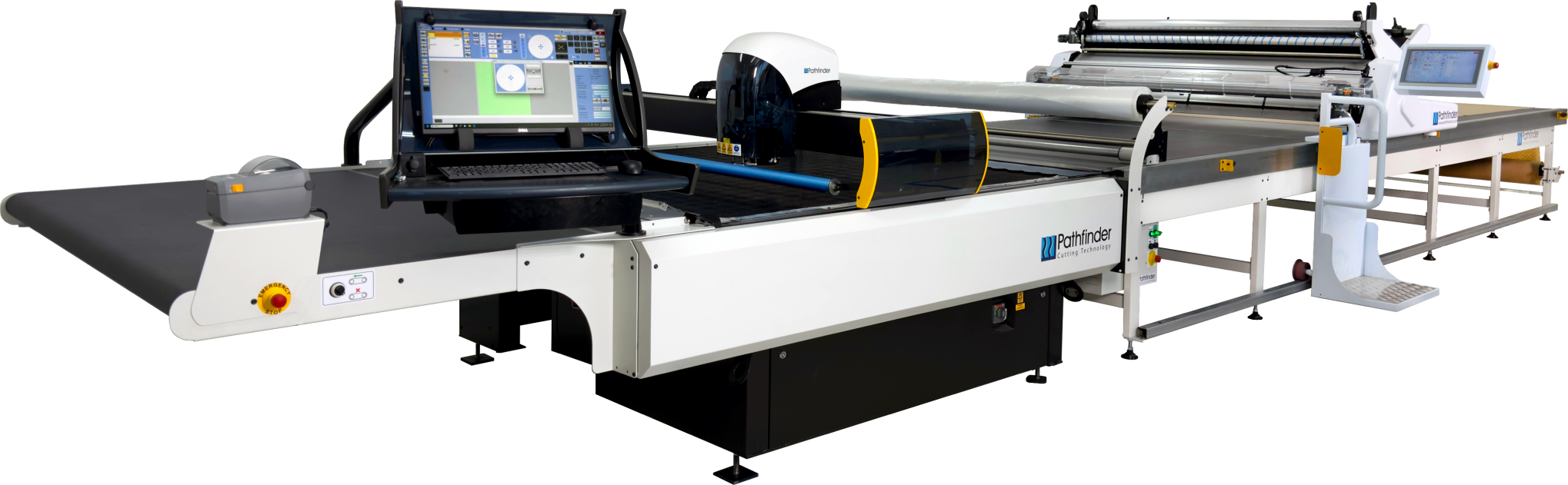

M-series multi-ply automatic cutting machine

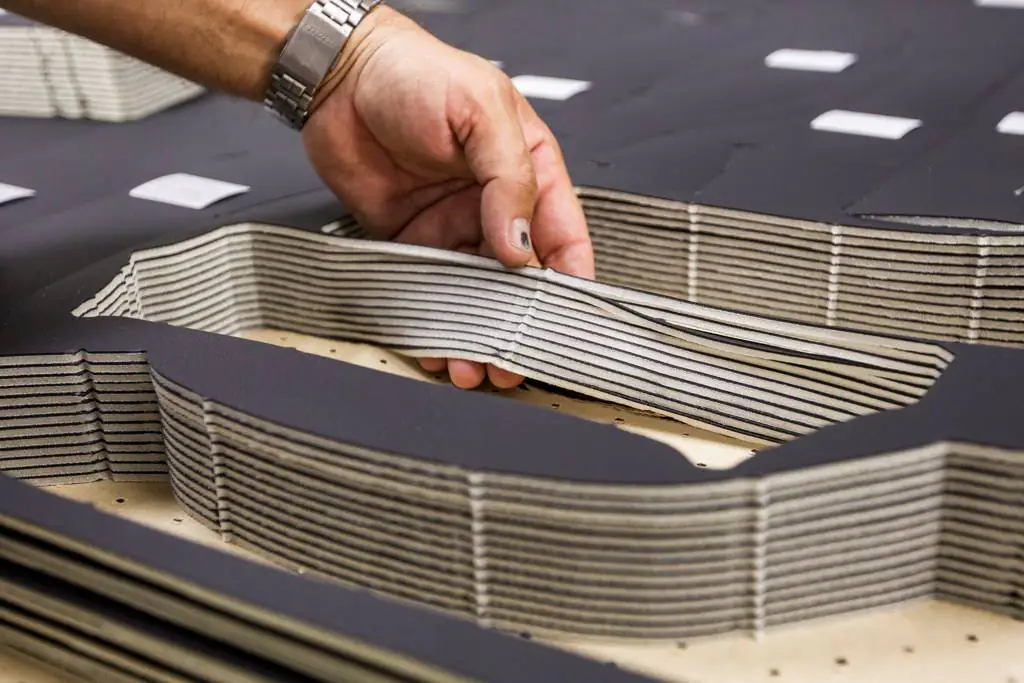

The M-series multi-ply automatic cutting machines deliver a robust industrial-grade solution specifically designed for high-ply production facilities and possess the capacity to effortlessly cut through up to 10 cm (3.9”) of compressed material goods.

Our customers are committed to delivering top-quality products while maintaining control of their cutting room operations. Many of them opt for the Pathfinder M-Series multi-ply automatic cutting machine as their preferred solution. Pathfinder’s multi-ply automatic cutting machines are renowned globally for their exceptional cut quality, efficiency, reliability, and affordable service. Leading brands around the world select Pathfinder to gain a commercial edge that sets them apart from their competition.

One satisfied customer shared how the Pathfinder multi-ply automatic cutting machine has significantly improved their operations, increasing cutting efficiency from 82% to up to 90%. This efficiency boosts streamlined production, leading to faster and smoother distribution of products across the factory and enhancing overall workflow.

The new Pathfinder M-Series, comprising 12 different models, is designed for low-maintenance operation compared to other brands. These durable, high-performance machines feature Pathfinder’s proprietary PathCut operating system, which offers an easy-to-use, high-productivity interface. Cutting room staff will appreciate the highly efficient vacuum compression system, enabling accurate, high-speed cutting up to 3.9 inches, paired with Pathfinder’s Quickdraw Sharpening System.

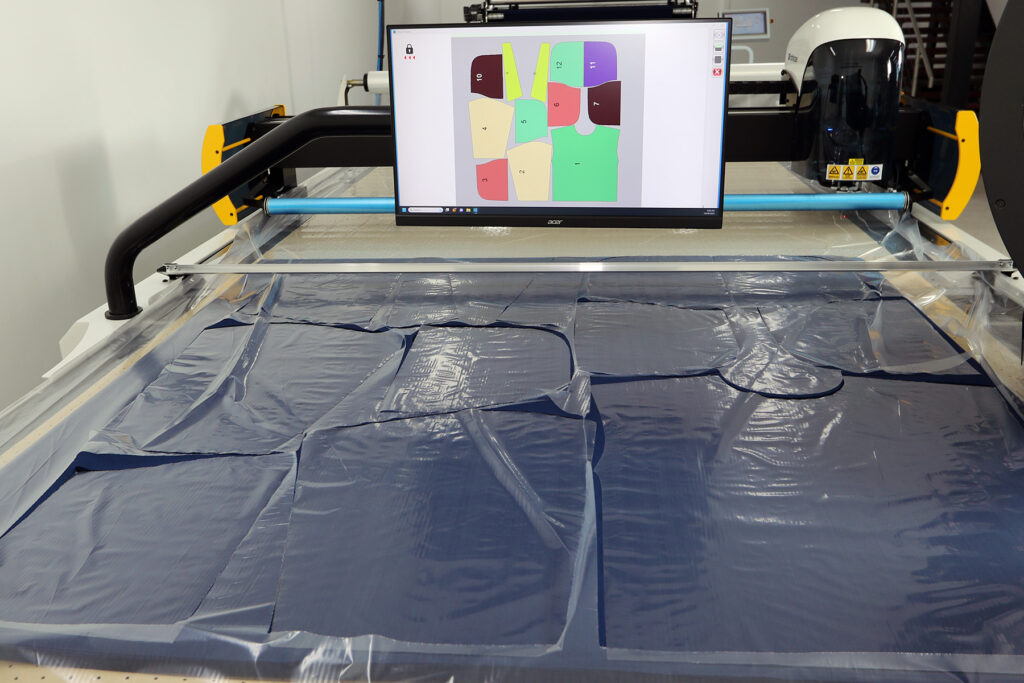

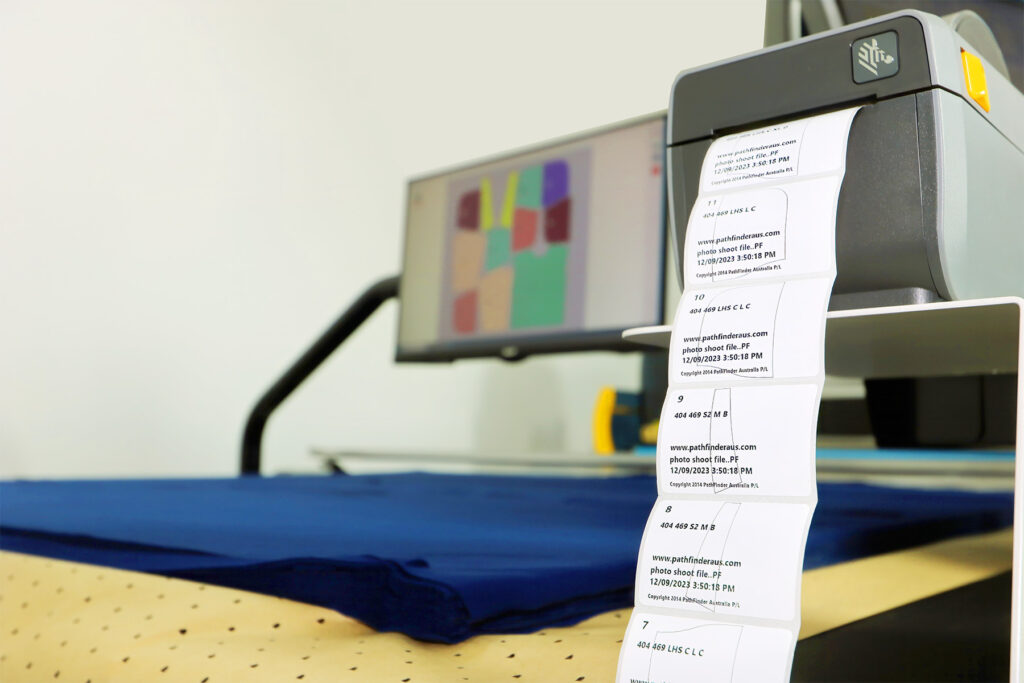

Additional features of the M-Series multi-ply automatic cutting machines include fast conveyorized material advancing, barcode scanning, synchronized label creation, an integrated multi-point safety system, and automatic synchronization of the offload display. The M-Series is also compatible with various material spreading tables and offers a wide range of optional add-ons and upgrades to meet any fabric type or production requirement. These options include different piece identification marking methods, integrated production reporting, and consumable reporting and forecasting features to enhance productivity further.

Pathfinder’s world-class support and servicing reinforce the advantages of choosing their multi-ply automatic cutting machines, helping businesses maintain a competitive edge. Pathfinder’s commitment to innovation, efficiency, and customer satisfaction is evident in every aspect of its cutting-edge technology, making it the go-to choice for businesses looking to stay ahead.

Advanced CNC oscillating knife cutting technology

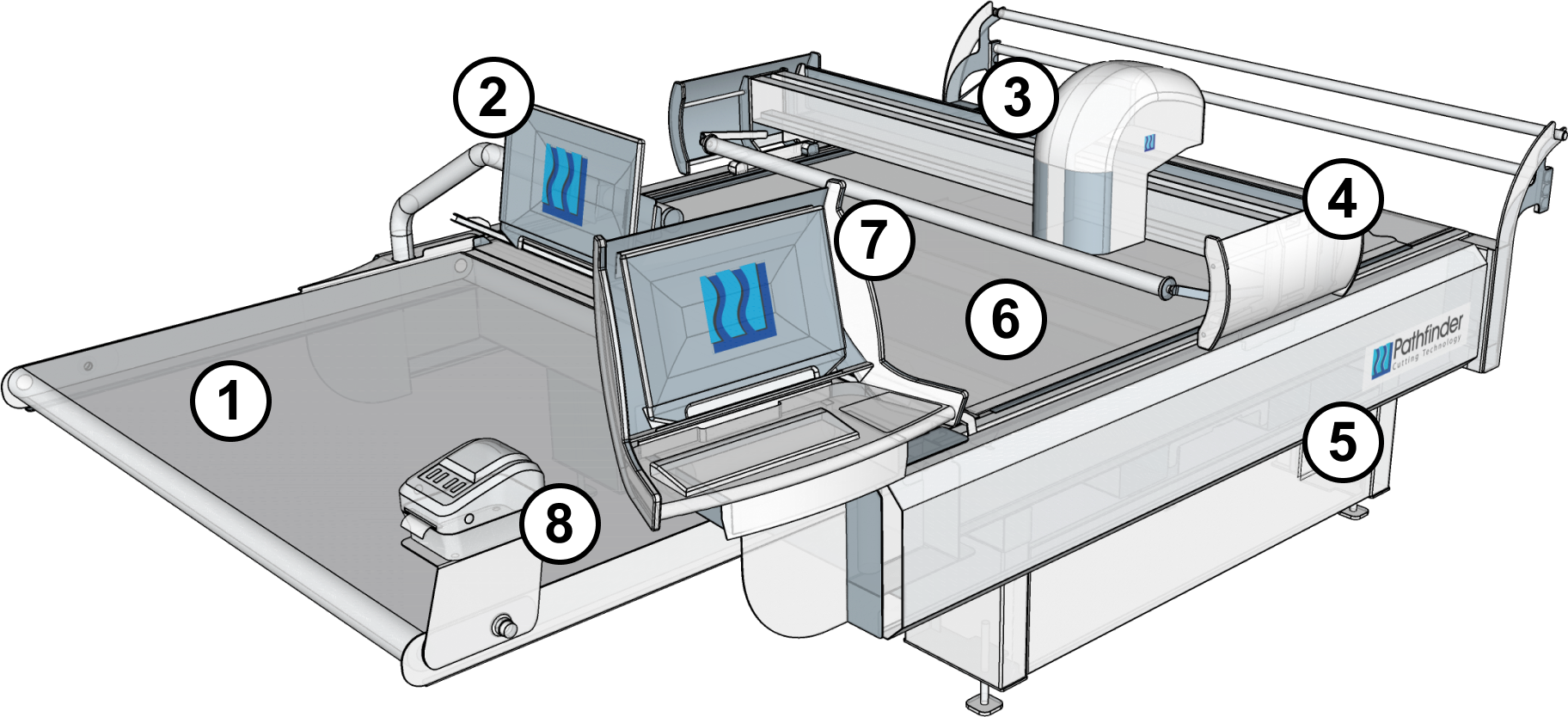

There are 16 Models available in the M-Series range of automated fabric-cutting machines. Discover how an automated fabric cutter will maximize your productivity!

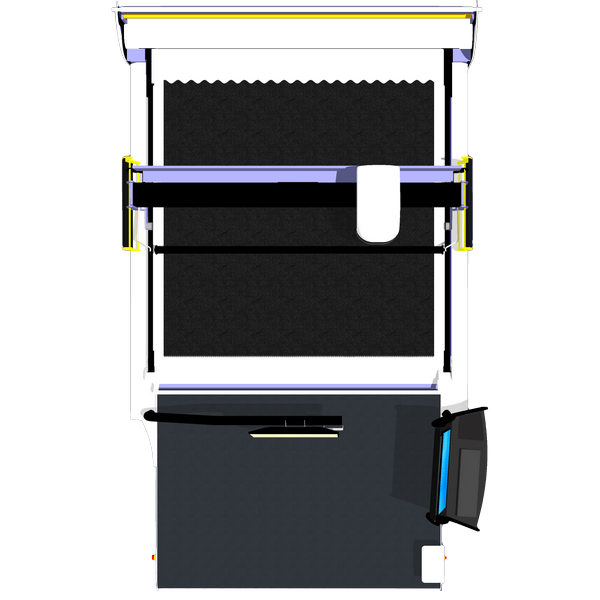

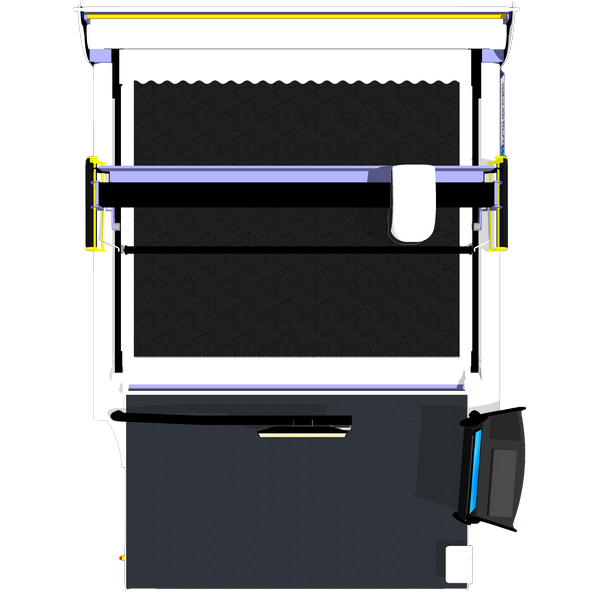

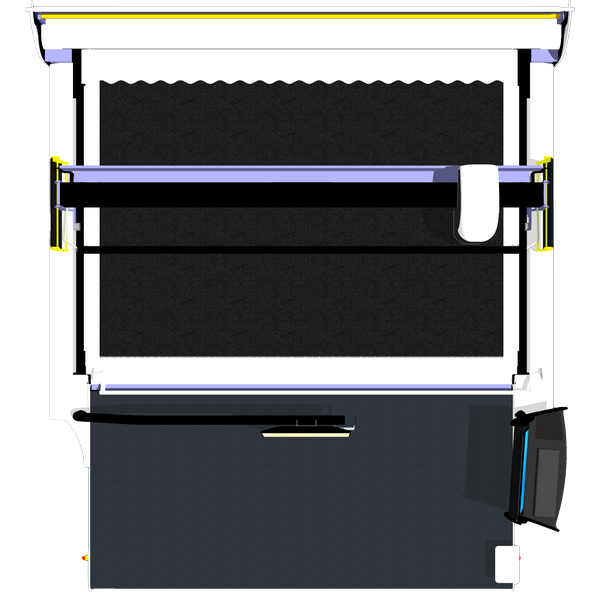

- Offloading area

- Offload display

- Cutting head

- Safety system

- Control system

- Cutting area

- UX (User experience)

- Offload printer

Features

- World-leading technology

- High productivity

- Optimal material yield

- Easy to learn interface based on Windows®

- PathCut® cutter operating software

- Digital Vacuum control

- QuickDraw® automatic diamond sharpening system

- Import all standard industry files – DXF, HPGL, ISO RS274d, NTV, ESSI, etc

- MultiCut™ queuing of nested files

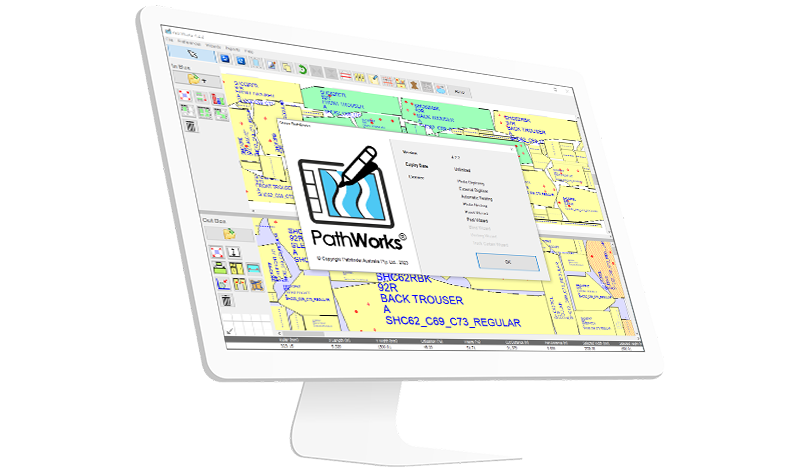

- PathWorks™ – all-in-one digital solution

The Pathfinder M-Series® range of multi-ply automated fabric-cutting machines is known for precision, high productivity and reliability at the lowest power consumption. All 16 models (4 cutting width options x 4 cutting heights) are easily configured to suit most cutting applications. Thanks to clever design, Pathfinder cutters require very little maintenance to continually deliver exceptional cut quality over a long working life.

4 Cutting Widths

4 Cutting Heights

(compressed by vacuum)

Loaded with Standard Features

The M-series cutting system features groundbreaking technologies to ensure your productivity is boosted and profits are maximized.

- Windows® operating system

- PathCut® cutter operating software

- Touch Screen user interface

- Utility drawer

- Laser Spot

- Drilling device

- Digital Vacuum control

- Vacuum Re-sealing blind*

- Dynamic vacuum monitoring & regulation

- Vacuum exhaust filter

- Vacuum Economiser® power saving function

- QuickDraw® automatic diamond sharpening system

- Automatic bristle cleaning

- Import standard industry files – DXF, HPGL, ISO RS274d, NTV, ESSI

- Common line deletion – dynamic ‘on the fly’ calculation

- Notch identification and transformation

- Drill hole identification and transformation

- Cut line proximity awareness

- Automatic cutting window calculation – ‘Whole piece cutting’ where possible.

- Zoom & Scroll graphic finger gesture’s

- Piece & cut order identification

- Self diagnostics

- End Cut – Operator programmable

- Cutting small pieces first – user definable

- Automatic knife & sharpening stone wear compensation

- Pre-set cutting parameters

- Multi-level user access – parameter protection

- MultiCut™ queuing of nested files

- QuickPath™ automatic cut piece ordering to reduce dry haul

- Integration- automatic cut job queuing, cutting list status & Completed marker list

- Automatic Selvage waste cut at programmable intervals

- Self Adjusting software parameters optimising cut quality

- Marker manipulation features, notch selection, rotation, flip, drill ommission, scaling etc

- Conveyor advance pause – automatic user definable

- Automatic conveyor load assist – distance & time user definable

- Automatic pause at piece selected

- Selection of pieces – do not cut

- PPR – Pathfinder Proportional Reciprocation

- Automatic lay width checking

- System history file – production cut file verification

- Power Fail Re-start sequence – itegrating intuitive operator prompts

- Maintenance Manager – automatic reporting of maintenance requirements and schedule

- Head parking – user definable

- Units display in metric, imperial/yards and inches

- Flaw avoidance – automatic piece movement avoiding material flaws

- Recut – Selection of single piece or from piece number

- Multi-language supported

*Available for Mx180 and Mx220.

Customise your auto textile cutter

Options to suit every application

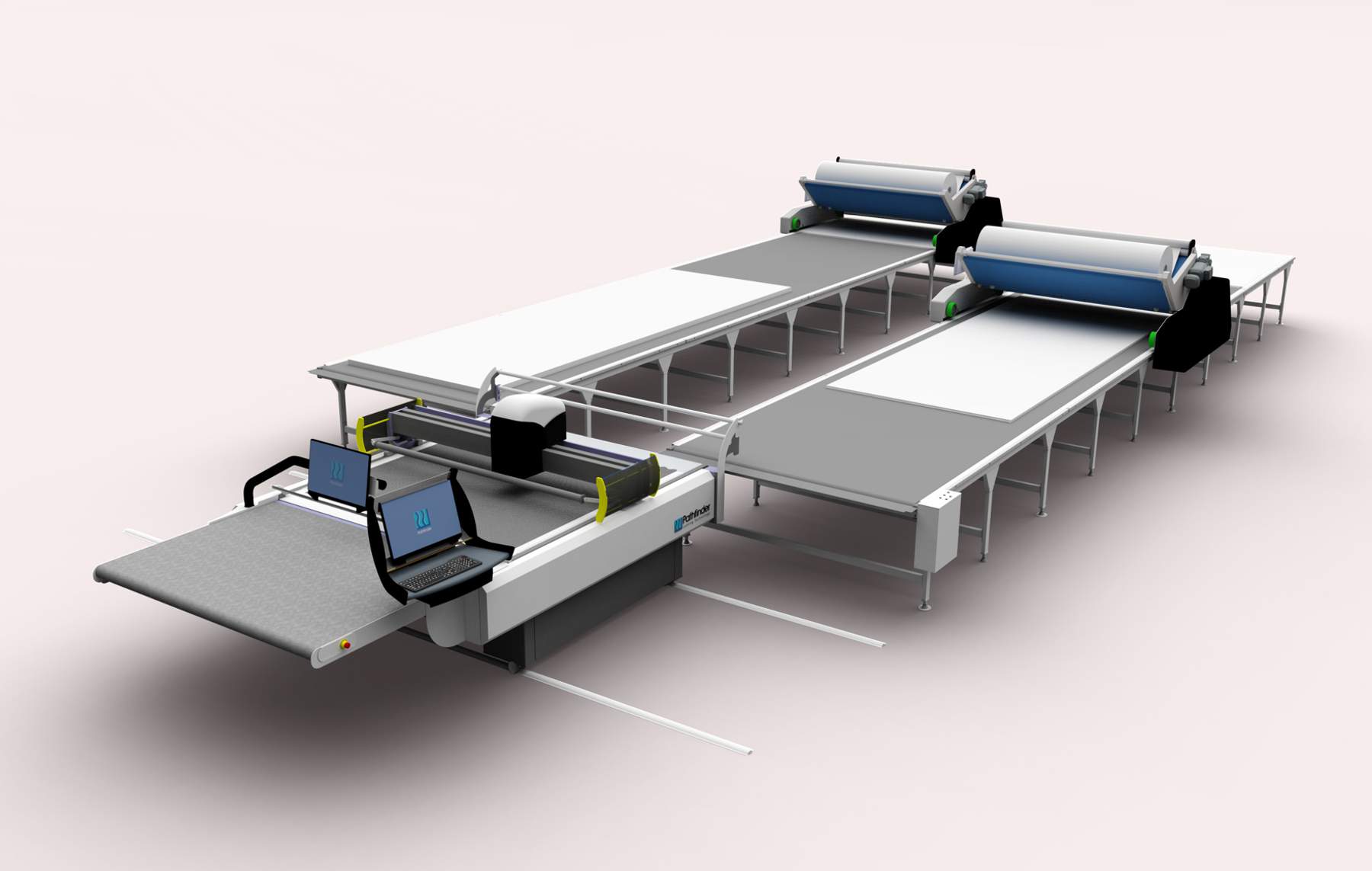

Every Pathfinder multi-ply automatic cutting machine can be enhanced with options to deliver unparalleled flexibility in production. Pathfinder CNC cutters are utilised in a diverse range of manufacturing applications including apparel, technical textiles and composites, furniture upholstery, and automotive seating.

Pathfinder offers significant advantages to manufacturers utilising knife cutting in their manufacturing process (clicker press/die cutting, hand knife or electrically driven knife).

- ABR (Airbrush) – non contact paint marking for difficult materials such as fibreglass

- AFP (Automatic Foot Pressure) – for special applications requiring multiple foot pressures

- ANT (Automatic Nesting) – automatic pattern nesting. (Available only with PTW)

- APM (Adaptive Pattern Matching) – Bow & Skew adjustments for stripes, motifs and pre-printed textiles

- BCR (Barcode Reader) – automatic opening of production using barcodes

- DR2 (Secondary Drilling Unit) – for drilling multiple hole sizes simultaneously

- DRG (Drag Knife) – ultra fine cutting tool for specialty materials

- HDC (Head Camera) – camera dynamically interacts with PathCut for Matching and other functions

- HFV (High Flow Vacuum) – used for specific applications where lofty materials used

- IJP (Ink-Jet) – mounted inside the cutting head used for printing part identification

- IKA (IceKnife-Air) – controlled delivery of air onto knife to cool and reduce fusing between parts

- LSC (LS Convert) – automatic conversion of native PLA & PLX file format

- MRK (Marking) – tool holder accepting a variety of standard marking pens-seam lines/text etc.

- MTS (Machine Transfer System) – allows the machine to move laterally to service multiple tables

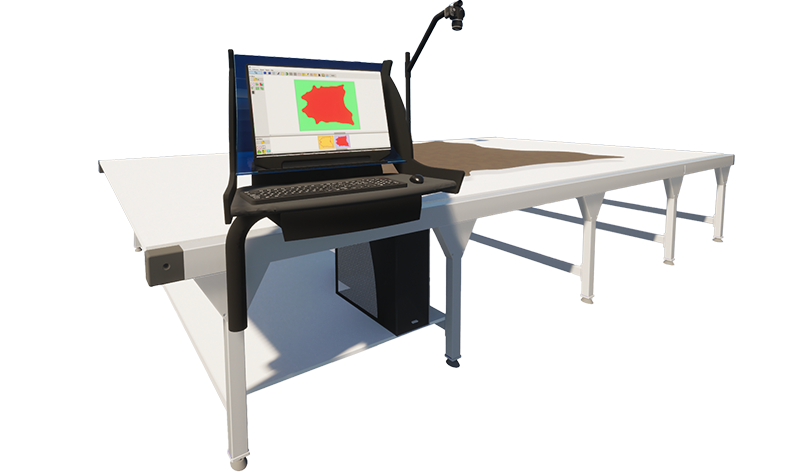

- OFD (Offload Display) – synchronised display of delivered cut parts

- OFP (Offload Printer) – adhesive label (50mm x 35mm) synchronised with OFD and delivered cut parts

- OFJ (Offload Projector) – synchronised projected display of delivered cut parts directly onto the material

- PTW (PathWorks™) – integrated within PathCut® enabling pattern creation and nesting

- PM (Pattern Matching) – aligns patterns across cut parts with pinpoint accuracy from any striped, plaid or motif material

- PRA (Production Analyst) – remote access to production manager data – standalone software

- PRM (Production Manager) – integrated production reporting

- R480 – Integrated Transformer 30KVA, 60 Hz, Autotransformer, Three phase. 480V(input).

Request more info

Want to know more? Full specifications are available on all of our M-Series cutting machines. To send you information that is relevant to your business please fill in the following details.

Combine Multi-Ply Automatic Cutting Machine With Other Products

Pathfinder presents a comprehensive end-to-end solution tailored to meet the needs of diverse businesses by offering a pre-established material cutting room. Irrespective of production scale, our cutting machines are designed to cater to even the most exacting requirements of enterprises.