Cutting the future

“There is plenty of profit to be reclaimed by introducing a more effective system and digital workflow into the cutting process”

Approximately $1.4 billion of waste goes into the ground per year!

CUTTING shapes out of expensive materials is a core business task in the Composites Industry – with potential hidden costs.

Curiously, many manufacturers continue to employ out-dated technology when cutting expensive composite materials and rely heavily on “some guys cutting with box cutters and scissors”.

The hidden cost of cutting

If you’re in Operations & Production Management, this won’t be the first time you’ve read about the need to improve production and material efficiencies, whilst lowering both the cost of production and the environmental impacts… you’ve heard it all before – right?

Well, on face value, a few guys “out the back” cutting materials by hand may not seem to be an issue worth investigation, but consider the costs that come with manual methods: Variability in quality, material under-utilization, time delays, additional labour, space requirements, excess scrap… and on it goes.

It should be obvious that there is some low hanging fruit and value to be reclaimed by introducing a more effective system and a digital workflow into the cutting process.

Dumping Profit

And consider this. In a recent online article in the Composite Manufacturing Magazine titled, “Upcycling Composite Prepreg Materials, One Step at a Time” the author highlighted the costs and negative environmental impacts of dumping pre-cured prepreg scrap material into landfill. To keep the math simple, the estimated volume of hazardous scrap going into landfill as quoted in the article is estimated at 29 million pounds (at a cost of $45 per pound before disposal costs), when you add management, labour and transport, the industry is putting approximately $1.4 billion of waste in the ground per year!

This statistic is neither lean nor green and emphasises the need for a better system for recycling composite material waste.

While there are many new technologies emerging for upcycling and recycling at both ends of the manufacturing lifecycle, the removal of waste from the outset is the logical place to address primary financial losses.

Why there is procrastination in addressing the waste issue

A recent survey of North American manufacturers, quotes that 89.8% of respondents are positive about the outlook for manufacturing moving forward, with many expecting to be hiring new employees and making new capital investments in 2018. This confidence would be further buoyed if the US Government is able to pass major tax reforms.

Yet despite these encouraging comments on balance, many manufacturers’ also flagged concerns regarding attracting and retaining a quality workforce, the rising cost of healthcare and insurance for employees, and the increasing costs for raw materials.

Taking all these obstacles into consideration, (from the recycling of hazardous waste to the mounting costs of employment), savvy manufacturers recognize that the time is right to invest in technology solutions that reduces material consumption and labor overheads.

By adopting CAD CAM technology that is both affordable and easy to implement – manufacturers can literally cut their way to better profits and environmental outcomes.

How CAD CAM technology in the cutting room addresses some of the issues

CAD (Computer Assisted Design)

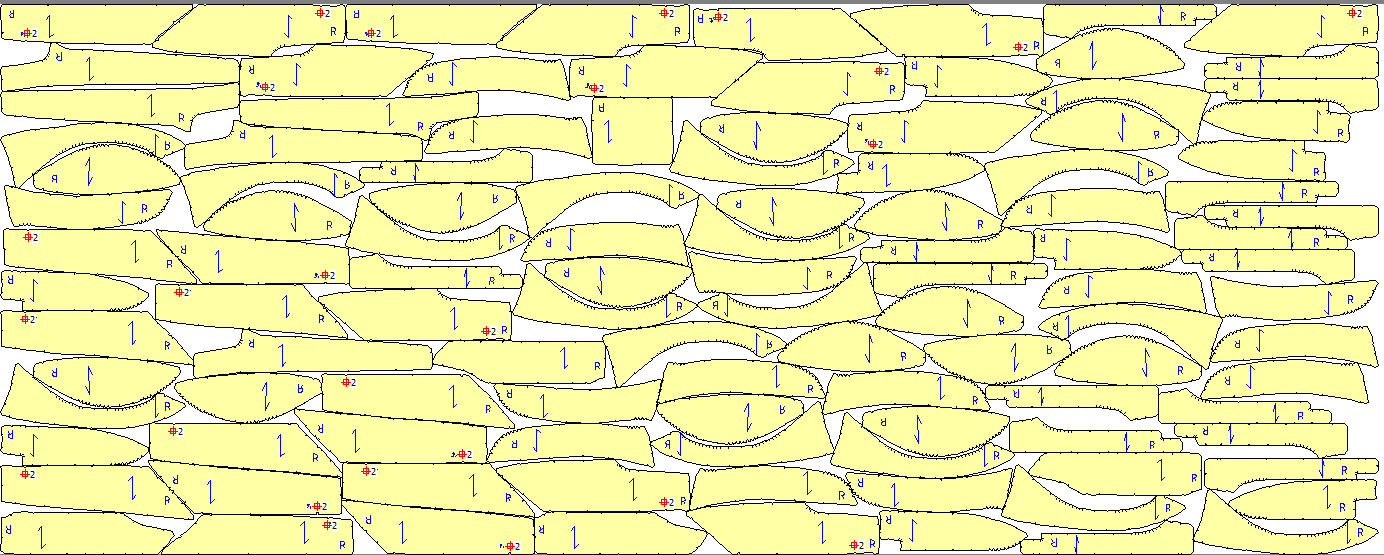

When production is governed by the computerized nesting of shapes (not by marking out templates by hand), there is an immediate and significant improvement in material yield, minimization of waste and the associated costs of disposal.

CAM (Computer Assisted Manufacturing)

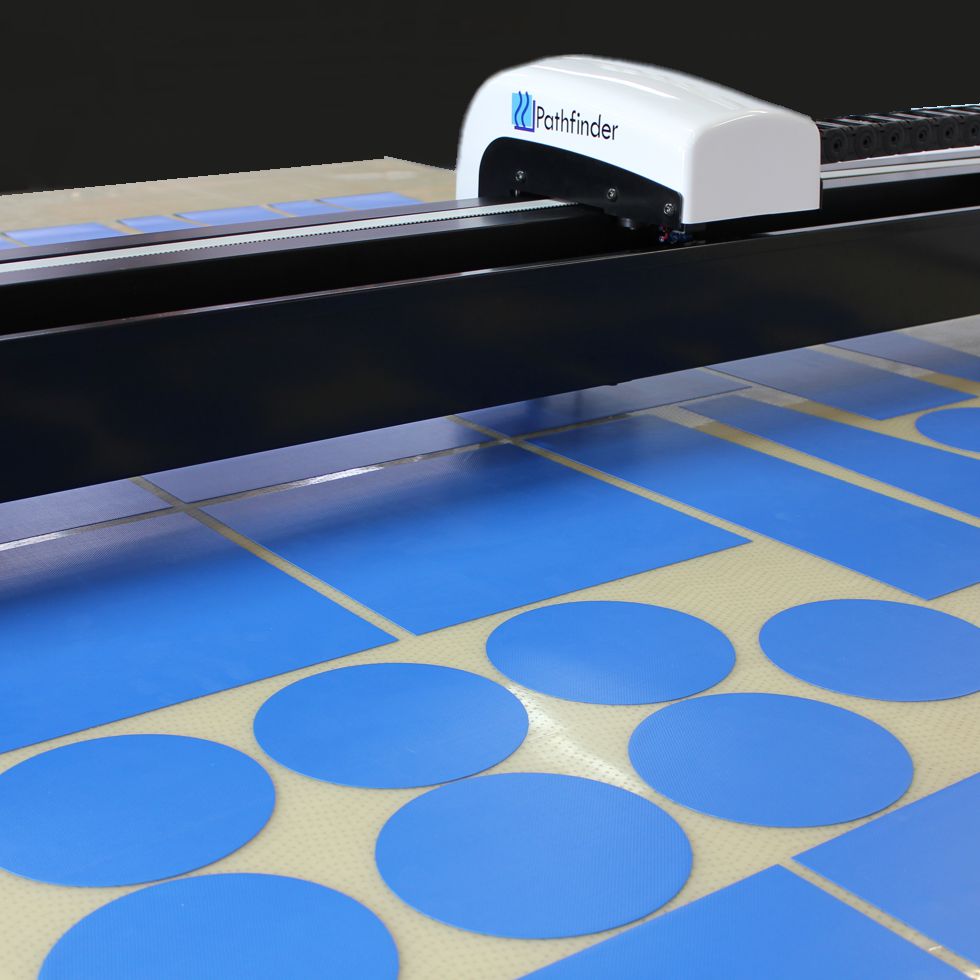

When combined with the speed and accuracy of CNC cutting technology, manufacturers can effectively replace the work of several employees’ hand cutting, ultimately reducing labor costs (and the associated costs of benefits, healthcare and management).

CAD software with enhanced material nesting algorithms and tighter cutting tolerances, allow for parts to be cut accurately and consistently at speed, increasing both total production throughout and production flexibility. This in turn, reduces both the head count and the amount of real estate required for production.

Basically, more production, at a faster rate, with less people and mistakes, generating less scrap that is going into landfill – not to mention the cost savings of all of the above.

As a recent example highlights, a customer in Tennessee started a project to measure the offcuts that were being trimmed in the moulds and dropped on the floor.

“ The status quo was it’s just a cost of business and that is how it is always been done … right?

It can’t be too much, it’s just trimmings going in the bin.”

The customer’s production engineers quickly quantified that this waste added up to about US$500k per year. Needless to say, the payback for implementing a cutting technology was very short and the project was quickly approved for CAPEX funding.