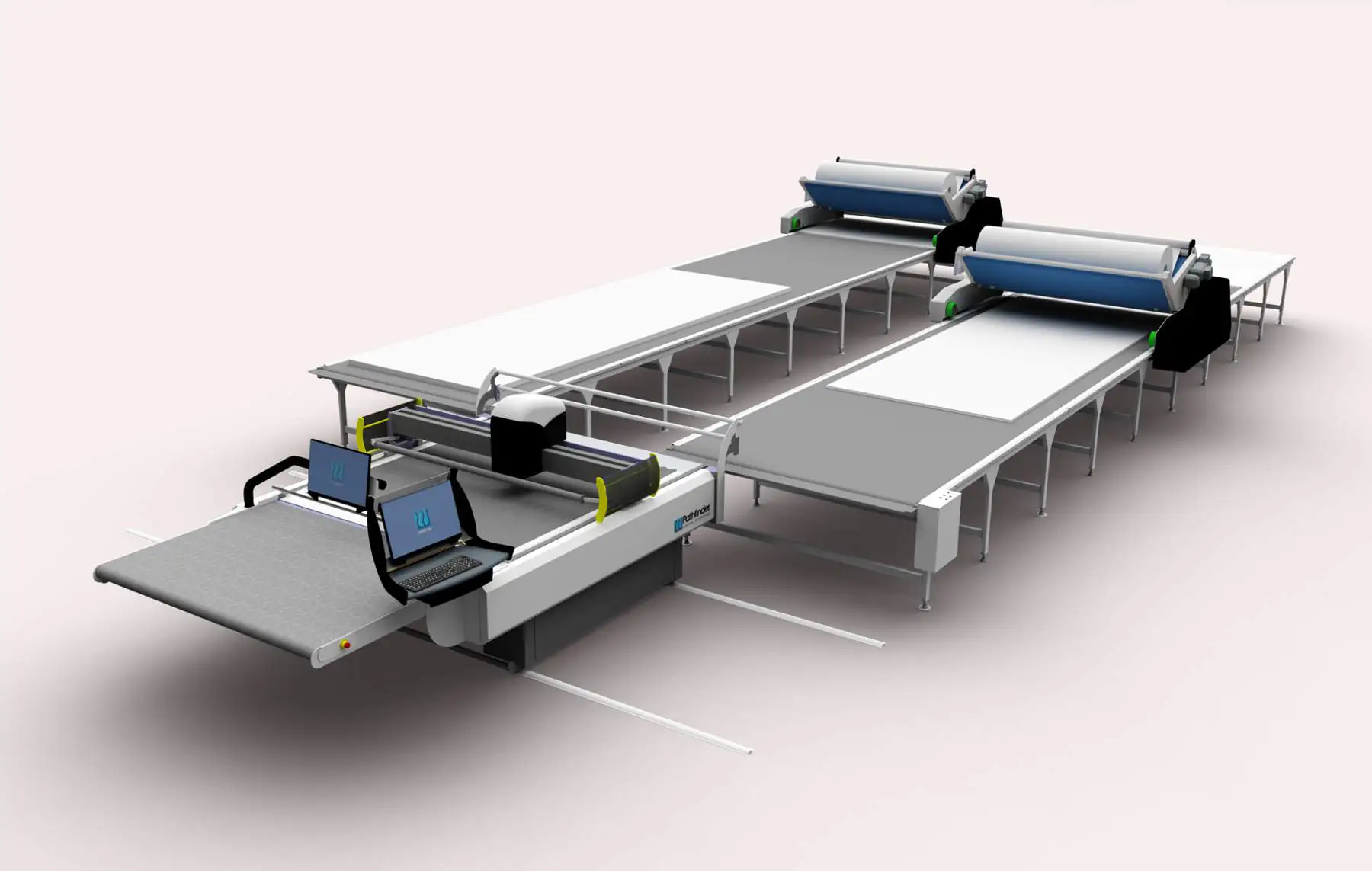

Conveyor Tables

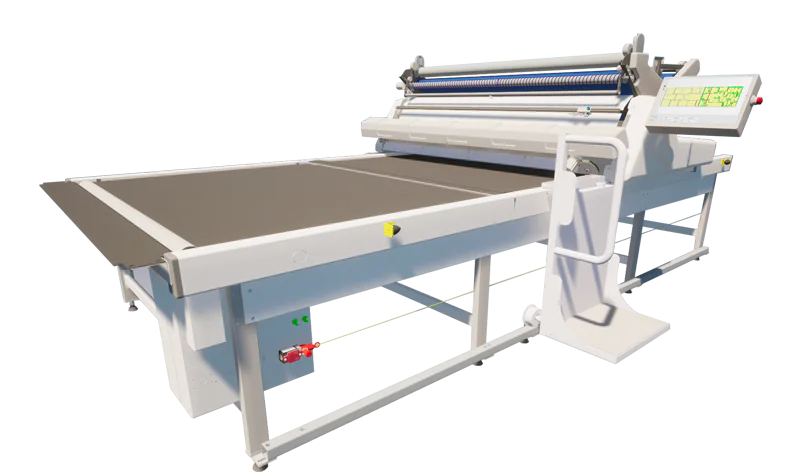

Maximize profits and increase productivity with the EasyLoader. A conveyorised table that simplifies the delivery of multi-layered spreads or rolled materials into the Pathfinder cutting system. Perfect alignment saves fabric, time and labour while eliminating rejected pieces due to fabric shifting outside the cut zone.

Thousands of dollars can be saved by improving nest efficiency. This can be achieved by confidently reducing the selvedge buffer.

Material Handling solutions that work

The Pathfinder EasyLoader™ is a conveyorised table that synchronizes with the Pathfinder cutter to enhance productivity and profitability. Effortlessly delivering perfectly aligned fabric or material sheets into the cutting system without requiring human intervention, The EasyLoader is available in various widths and lengths to optimize your applications.

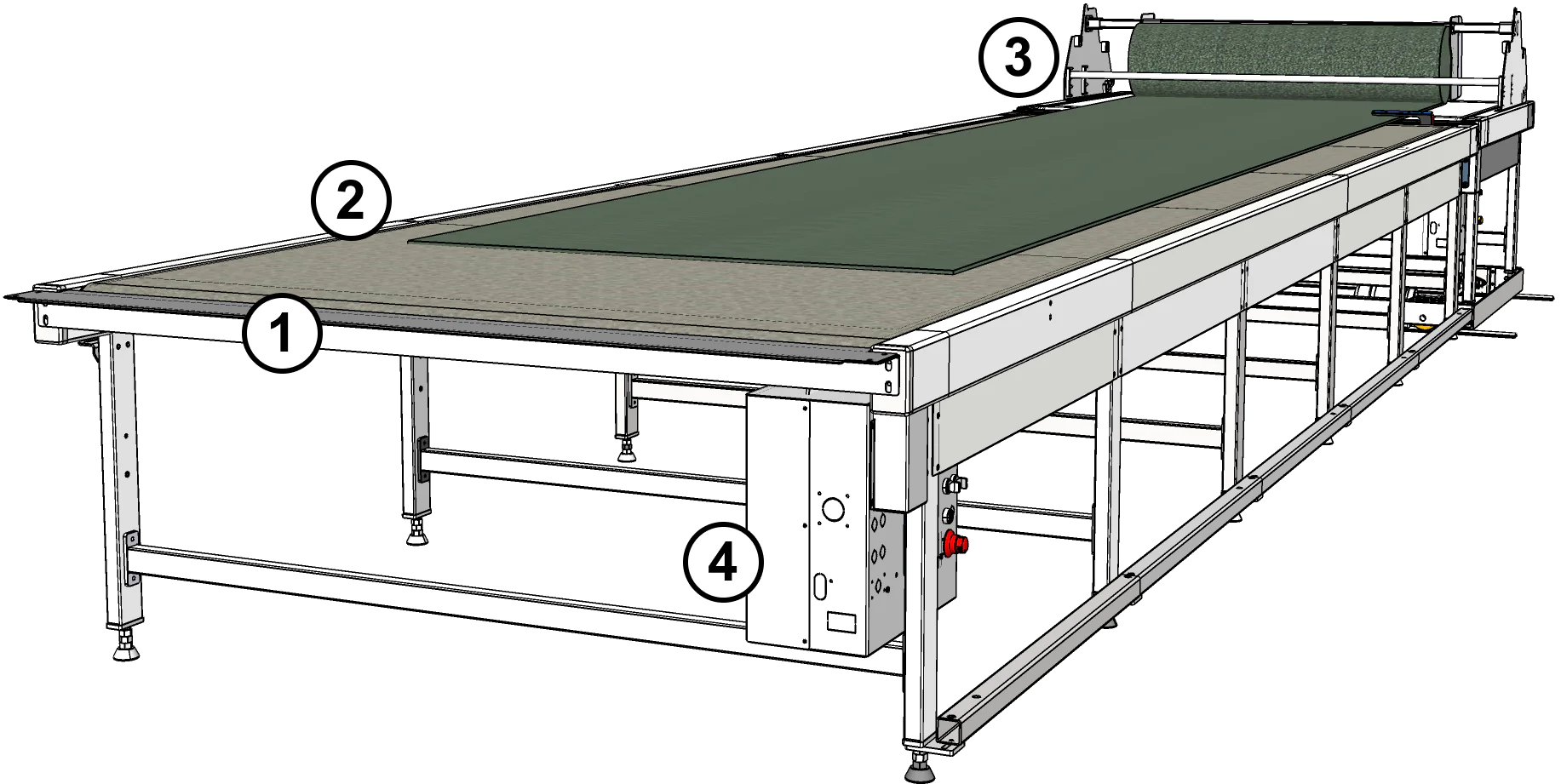

- Pathfinder Cutter junction interface

- Conveyorised Table

- Control Box

- Roll Feeder*

Features

- EasyLoader for Multi-layered Spreads

- EasyLoader for Rolled Materials

- Synchronization with Pathfinder Automatic Cutters

- Time and Productivity Savings

- Increased Material Yield

- Minimal Reject Pieces

Various Widths, Lengths & Surfaces

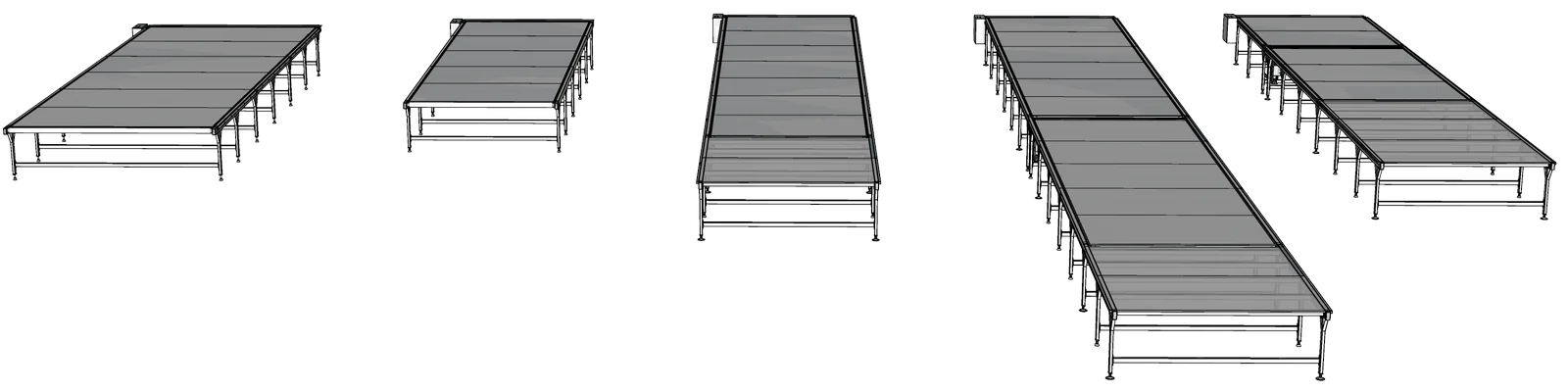

EasyLoaders are available in various configurations.

Widths – Various widths are available to suit your application.

Lengths – Modular design enables any length required to optimise your cutting room workflow.

Surfaces – Both conveyor and static table tops can be configured to best suit your application. Static table tops are often used at the end of a table furthest from the cutting machine. When a FabricPro spreading machine is installed this space is under the spreading machine and conveyorisation is not required.

Maximise your profits

The EasyLoader simplifies the delivery of rolled and multi-layered spread materials onto the Pathfinder automatic cutting system.

Multi-layered Spreads

After a multi-layered spread has been completed, it is necessary to move the spread along the table so that part of the spread is within the cutting zone of the auto cutter. The EasyLoader has a conveyorised surface that transports the spread material onto the cutting machine, reducing labour requirements and ensuring the spread is perfectly aligned.

Rolled Materials

In some applications, cutting directly from a roll or multiple rolls would be more efficient than cutting multi-layered spreads. The EasyLoader roll feeding device option will enable direct single-roll or multiple-roll feeding perfectly synchronised with the Pathfinder cutting system.

Synchronisation (with Pathfinder automatic cutters)

Perfect synchronisation will deliver even a single layer of flexible material without stretching or distortion. The synchronisation feature within the Pathfinder cutter eliminates the traditional ‘dancer bar’ which would not be possible with high-spread lays.

Increase material yield

Material is delivered perfectly parallel, which means the markers generated can be made wider

Minimal reject pieces

When the material is delivered parallel to the cutter misaligned pieces cutting into the selvedge are eliminated

Request more info

Want to know more? Contact us!

Combine with other products

Pathfinder presents a comprehensive end-to-end solution tailored to meet the needs of diverse businesses by offering a pre-established material cutting room. Irrespective of production scale, our cutting machines are designed to cater to even the most exacting requirements of enterprises.